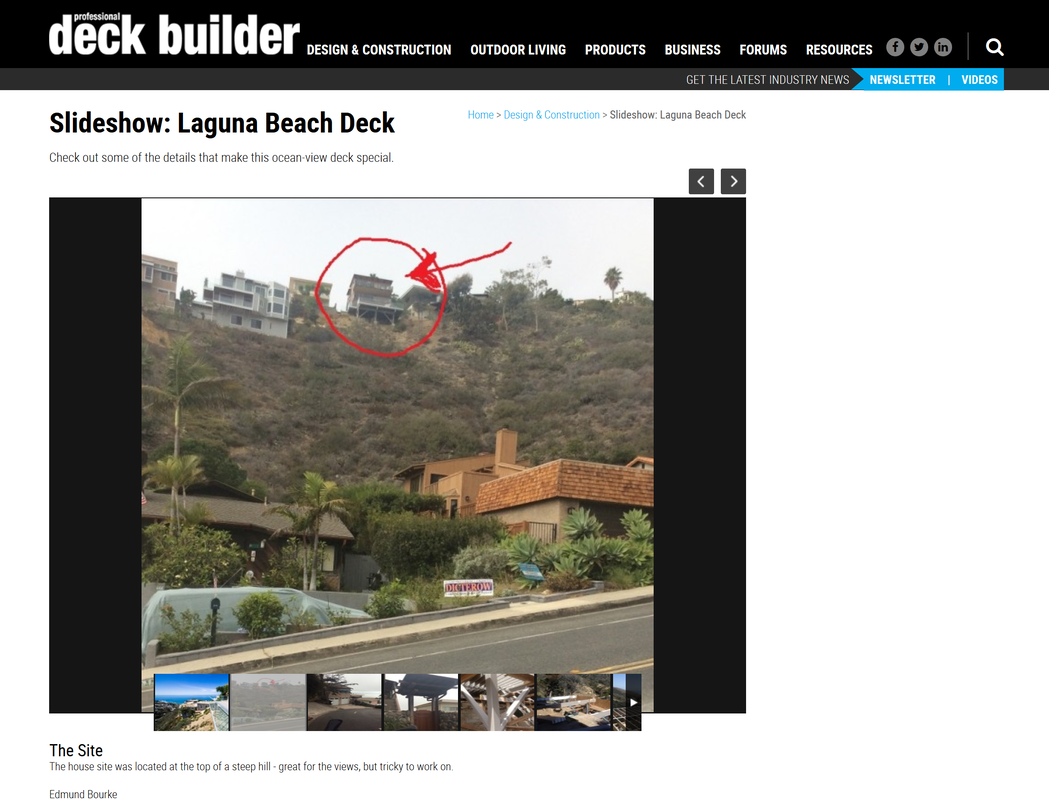

The logistics of our Laguna Beach, California deck remodel were featured in the trade publication 'Professional Deck Builder' recently. The captioned slideshow highlights our process and our abilities to overcome logistical challenges that may be intrinsic to your home and/or surrounding neighborhood.

Click here to read the article. Click here to schedule a complimentary consultation with us.

Click here to read the article. Click here to schedule a complimentary consultation with us.

RSS Feed

RSS Feed